DESKAR milling machine cutters are an essential part of the tool equipment used by machinists to shape things. They aid in cutting and shaping materials such as metal and wood into different shapes. Turns out the thing your shop is built around, the milling tools needed to cut all of those parts, shapes, and products out of raw material really is an interesting array of tools, and without them, it would be tough to make a car, toy or house, we are going to chat about how milling tools can get used and why machinists need a mill tool selection in their toolbox.

There are various types of milling tools, which differ in shape and size. End mills, face mills, and ball nose mills are three of the most widely used milling tools. End mills are let for cutting a straight flat surface while face mills will cut at an angle. Ball nose end mills are ideal for making curved surfaces.

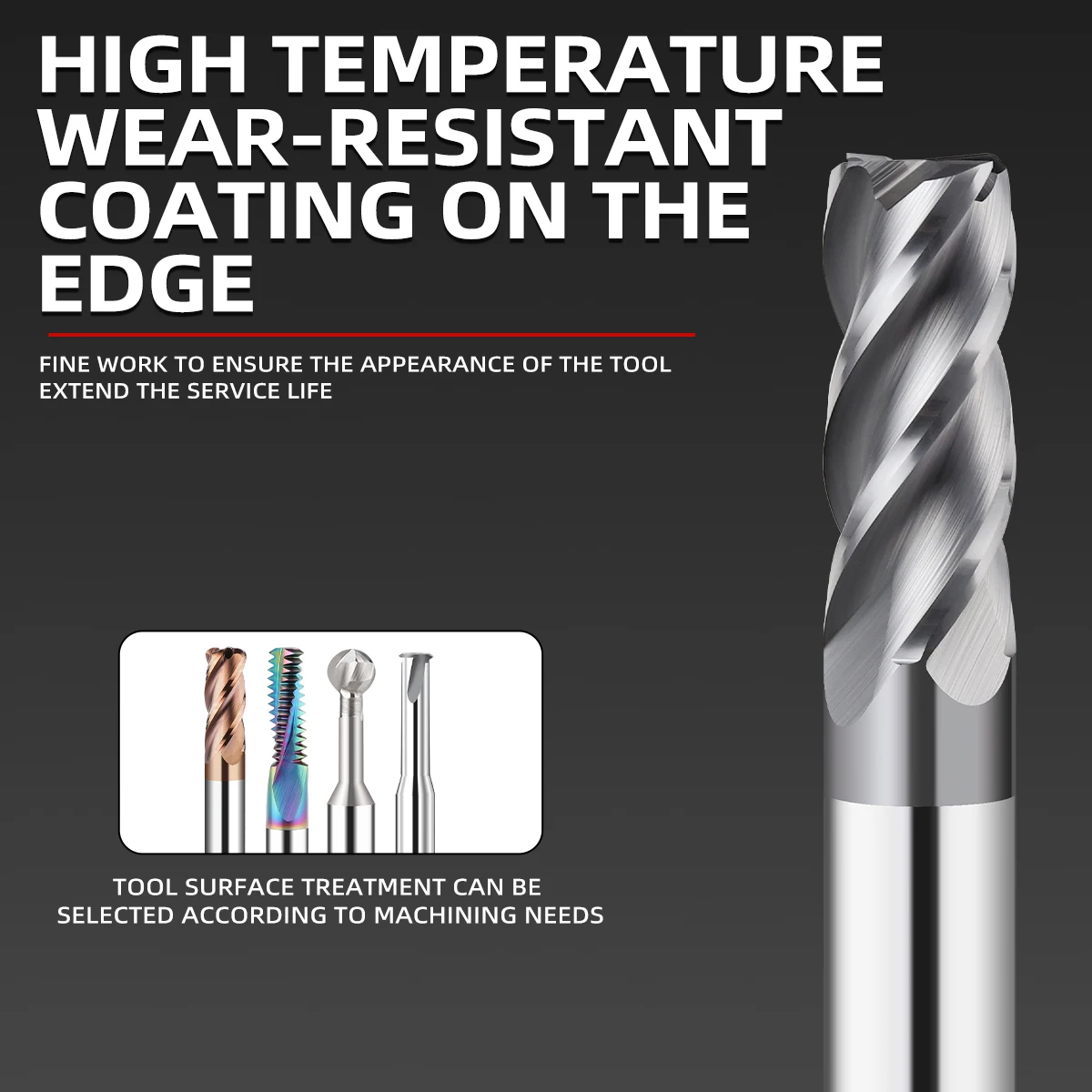

When selecting a DESKAR carbide end mill cutter, it is important to choose one that is appropriate for whatever material or operation you will be working on. Various styles of milling tools are better suited for certain materials and types of projects. For instance, if you’re handling metal, you will need a carbide end mill to give you both durability and a precision cut.

Machinists have a collection in add-on to milling tools, such as they do other tools they will rely on to get the job done quickly. Some of the tools that every machinist should have are a milling machine, a vise to hold materials in place, and calipers and micro-meters. These devices assist machinists in shaping and cutting materials to the specifications they want.

Learn the basics of milling you even attempt to read DESKAR face milling cutter, crackers such as seed crackers or dog food cracker recipes, it’s always useful to understand how they work and how to use them safely.

Select the correct milling tool goes without saying, but it’s worth repeating. Different types of face mill tool are more appropriate for certain materials and projects. Be sure to pick the right tool for the job.

Tools used for fly cutter mill are essential for increasing the process productivity. Machinists can get the job done quickly and with a great deal of accuracy by using the right tool for the task. Moreover, milling bits eliminate the need to stop if a clean and accurate cut has been made, eliminating both time and waste.