Mill cutters are essential tools in the making of things out of metal or other materials. These instruments vary in shape and size, and each type is designed for a specific task. In this article we are going to discuss mill cutters, and how they can help you do better work on the items you are producing.

A mill cutter is a tool that removes material from a workpiece that you are machining. They come in many forms to serve various functions. Slots, pockets or shapes, mill cutters can produce them with high precision.

People used to manually hand the mill cutters. They were known as machinists, and used tools to do their work. Newer machines known as Computer Numerical Control (CNC) machines are used more frequently now. These machines move the mill cutter using a computer, which can make things more accurate and faster.

When selecting a mill cutter for your work, consider the type of work you'd like to do and control materials you're cutting. Various mill cutters work well with certain materials and jobs, and it is important to know what type suits your situation the best. With so many mill cutters with assorted profiles we can help you find the right tool for the job.

In order to work better with your mill cutter, here are some tips: First, use the correct speed and pressure based on the material you’re cutting. That prevents wear and tear on the tool and allows for a clean cut. Don't forget to consistently maintain your mill cutter. And keep things cool, if you do use coolant or oil, help your tool last longer.

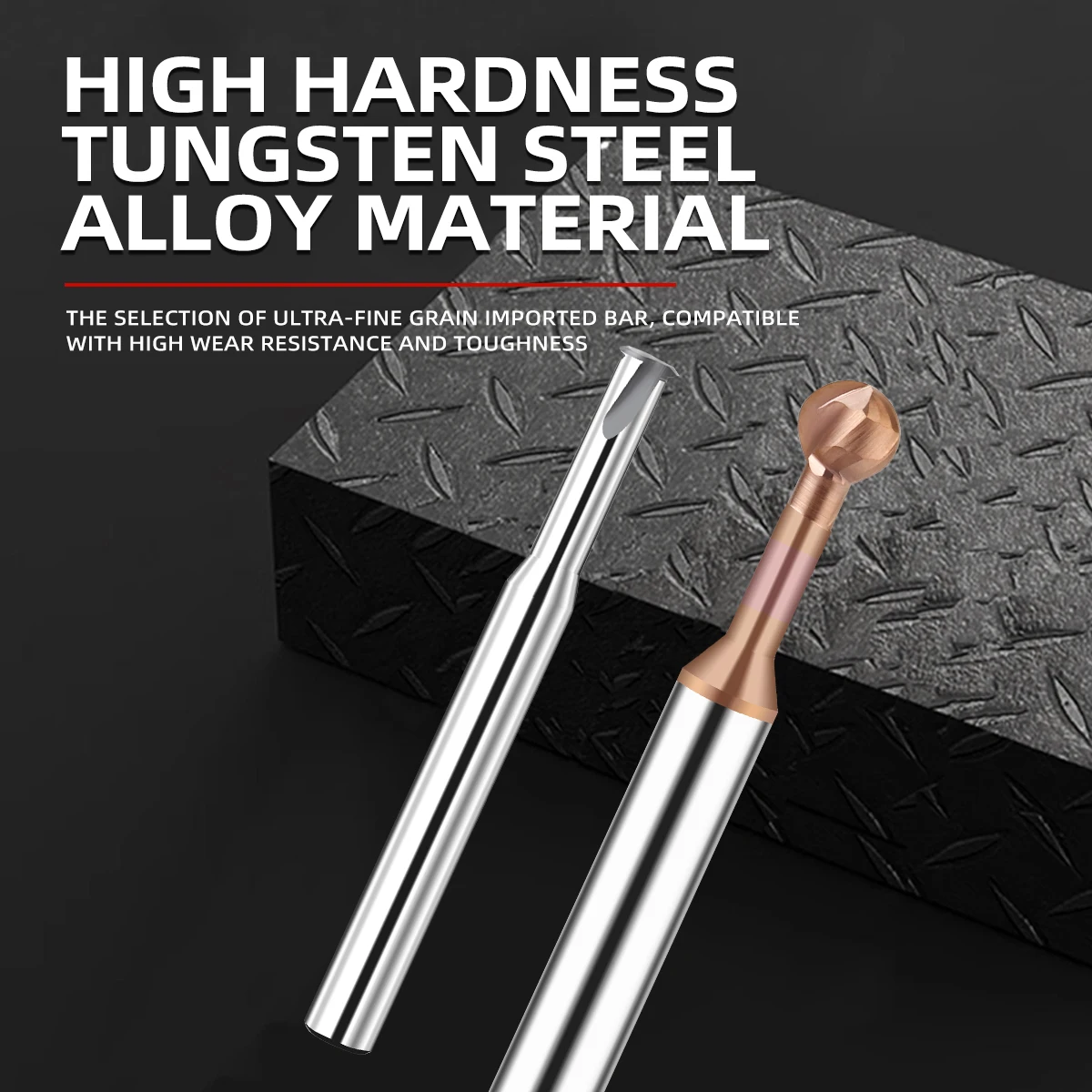

There is a vast array of mill cutters available for different operations. They are regularly used by end mill, roughing cutter, and ball nose cutter. End mills can handle many cutting tasks, while roughing end mills quickly remove large amounts of material. Ball nose: These tools have a rounded cold, but the cutting path is curved because of the 3D rotation of the cutting edges. Understanding these types, can help you decide which tool is best for your project.