Metal Milling bits are crucial tools for shaping and cutting metal materials. These bits are used in appliances such as lathes and mills in order to achieve delicate and high precision designs on metal surfaces. If you are a novice to a veteran machinist, you know that the quality of your work can be greatly affected by having the right metal milling bits so in the following post, we are going to delve into the best metal milling bits for precision machining, the newest metal milling bits, how to choose the perfect bit for any metal, how to take care of your metal cnc milling bits to make them last longer and how to customize the bits for optimum results.

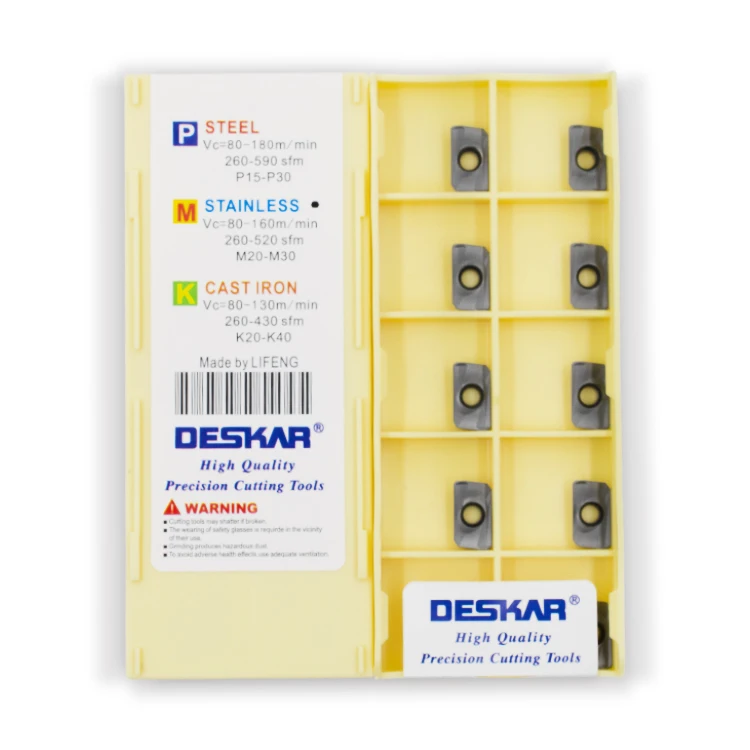

High quality and milling cutter design when doing precision machining. DESKAR's variety of milling bits are an excellent point of reference to ensure a high quality finish in a variety of metal working applications. Their tungsten-carbide-tipped bits are among the very best and should have no problem cutting through hard metals, including steel and aluminum. DESKAR’s cobalt bits are also widely used by machinists because they can handle high-temperature and fast cutting speeds. Whether it's steel or shouldered bushing, DESKAR has the Carbide milling cutter bit you need.

The Latest Innovations in Metal Milling Bits You Should Explore. Metal milling bits are always subject to innovation, and new research and development may lead to the faster, more effective materials and designs. DESKAR is a leader in producing innovative metal cutting tools, and engineers and researchers of this company consistently work on the most effective tools, and machinists can choose from a variety of cutters to find the one that suits their needs. A diamond-coated cutter is the milling tool designed with a thin diamond coating that provides the best wear resistance and cutting performance. Top machining speeds and longer than average milling time are ensured with this tool. Make sure to keep an eye on the innovations developed by DESKAR in metal milling blade bits to have the edge in metalworking projects. Finding a proper metal milling bit is an issue for those who work with different kinds of metal. Depending on the metal’s hardness, type of cutting, and the desired finish, the machinist must choose different cutting speeds, feeds, and tools made of the different materials. DESKAR offers a wide range of metal milling bits available in diverse materials and coatings. They can be HSS for soft metals or carbide-tipped cutters for tough materials.

If you would like to achieve longevity with your metal milling bits, do give them proper care and use these few maintenance tips. One of the best ways to extend the life of your bits is by not overheating them while using them. Too much heat can cause the edges to dull faster, compromising the bit's efficiency. Use cutting fluids or appropriate lubricants when working with metals to keep them from overheating, and adjust your cutting speeds and feeds accordingly. This will aid in maintaining a consistent cutting edge Regularly check raw milling bits for wear or damage, replace them as necessary to achieve good performance.

To get the best performance from your metal miking bits you should use them in ideally designed, precision ground tool geometries with cutting speeds and feeds optimized for your material and cut. DESKAR has different sizes of milling bits, each bit is with geometry cutting, coatings and smaller bits. which can help you solve different project problems. High-speed steel bits with a 3-flute design for increased cutting speed for roughing cuts. For the final cut, use carbide tipped bits with smaller flutes for the best finish quality. If you choose the right milling bit and set your cutting parameters well, you will be able to work very well and with a high quality end in your machining projects. If you belong to that group of people who think that the results achieved with metal milling are bad, I am sorry to tell you that you are mistaken.