End mills are a kind of special cutting tools for machining. They assist with cutting and shaping materials, such as metal or wood, with great precision. If you would like to learn more about end mills, then make sure you continue reading this blog post from DESKAR!

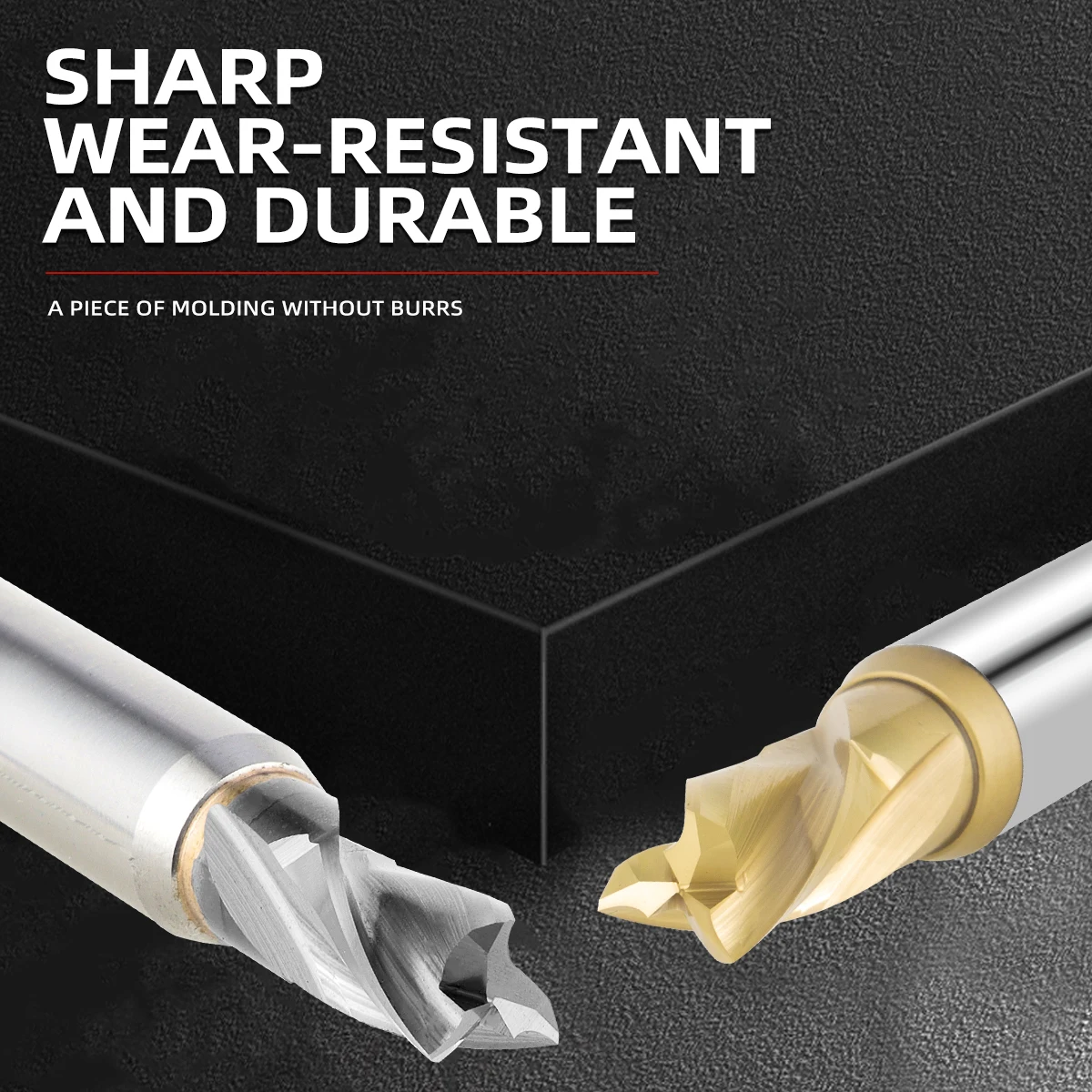

End mill tools may enable you to make sharp cuts in a wide variety of materials. These are sharp, rotating tools that cut and scrape material away. Selecting the right end mill tool for the job is essential to achieve the desired results. Always follow the safety instructions when using these tools to prevent accidents.

End Mills Tips have literally transformed the way we are able to cut materials. They help us use tiny designs, patterns and shapes. In the pre-history of these two tools, it was tough to make the cut. Today, machinists can easily create parts and products. DESKAR has a large variety of end mill tools to choose from.

There are a variety of types of end mill tools, and each is designed for a specific purpose. END MILLS A variety of end mills are available including flat, ball end and corner radius end mills. Flat end mills are for cutting flat areas, and ball end mills have a rounded cutting edge to make a curved surface. Radius corner end mills are good for cutting sharp corners. Understanding the differences can helpp you select the proper tool for your job.

To get the most out of your end mill tools, there is a common maintenance routine you should follow. Storing your tools in a clean, dry location is the best way to prevent corrosion. Clean your tools of any residual materials, after using them. If you use a special liquid fluid (link) covered by Suppen, the blade will not get too hot when you cut. With these tips, you can keep your tools in excellent condition for a very long time!

When choosing an end mill for your project, think of the material you’ll be working and the type of cuts you’ll make, including the kind of surface you want to achieve. Varied tools are required for different materials. For instance, harder material such as stainless steel may require harder carbide end mills. The pace you cut will also depend on the material you’re using. Finally, consider how smooth you’d like the surface to be. Roughing end mills are suitable for fast cuts, and finishing end mills can make smooth surfaces. DESKAR has countless solutions to help you pinpoint the device you need for the job.